AAC BLOCK PLANT

Dongyue Machinery Group AAC block production line has been introduced from Germany and reformed, and now it has entered the innovative research level. The manufacturing process and equipment of aerated block production line have been exported to Uzbekistan, Kazakhstan, Cambodia, Myanmar, UAE, Mongolia, India, Bangladesh, Indonesia, Vietnam and Nepal… etc.

Dongyue Machinery Group SAND AAC Block plant has the following characteristics:

01

RAW MATERIAL PROCESSING

deep grinding of quicklime, cement, gypsum, aggregate (sand), so that the fineness of the specific surface area of 4000 cm 2/ g or more, promote more active ingredients to participate in the reaction, improve the strength of autoclaved aerated blocks, and because of deep grinding, the slurry prepared by raw materials is more viscous, more favorable to the stability of pouring.

02

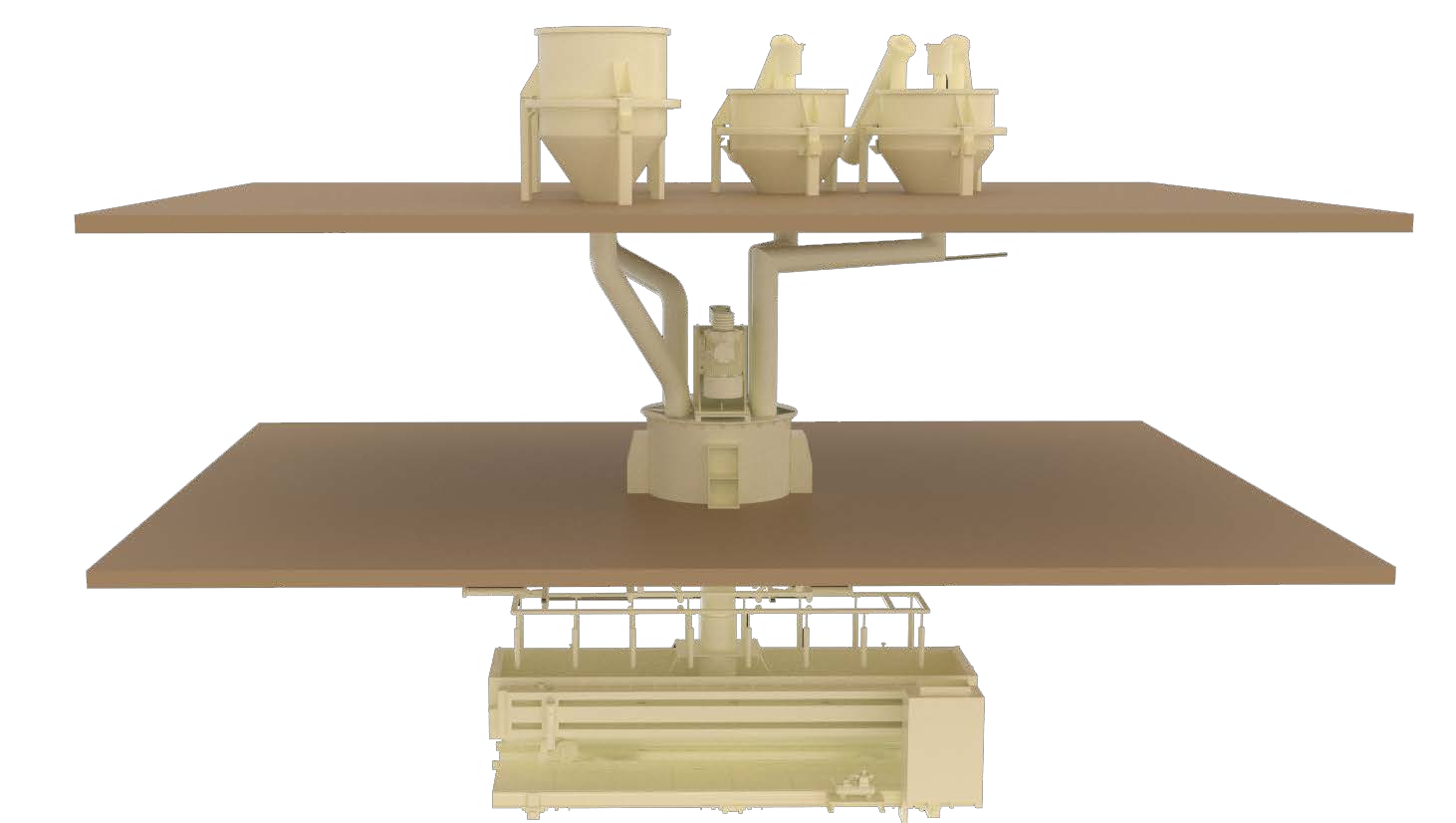

PLC AUTOMATIC BATCHING SYSTEM

the automatic batching control system of aac block plant, its simple operation, clear interface, high degree of intelligence, stable and reliable performance, simple system configuration.

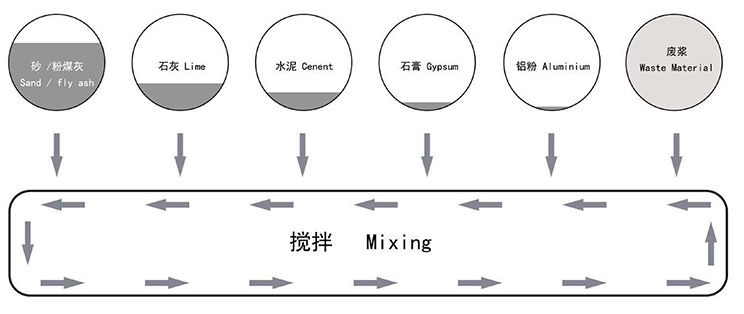

aac blocks are mainly composed of lime, cement, gypsum, aluminum powder, sand, lime and cement as a cement, gypsum as a hardener, aluminum powder as a air agent, by microcomputer control according to a certain proportion of ingredients, mixing tank opened after a certain time after automatic discharge, when the slurry discharge is completed to send out empty signal, transport reamer operation, at the same time aluminum powder stirring start, after a certain time, If the temperature of the mixing tank meets the requirements, the lime and cement will automatically feed, when the lime and cement feeding is finished, the empty signal is issued, after a period of time the transmission reamer stops running, and then after a certain period of time, the aluminum powder stirring automatically runs at the same time the aluminum powder automatic feeding, and then after a period of time, the mixer automatically stops, and begins pouring, to the end of this working process, The system waits for the next work order. The feeding of the measuring scale (feeding from the silo or slurry tank to the metering tank) and feeding are interlocked, only after the feeding one the other can be fed, the Simultaneous feeding process is prohibited.

aac blocks are mainly composed of lime, cement, gypsum, aluminum powder, sand, lime and cement as a cement, gypsum as a hardener, aluminum powder as a air agent, by microcomputer control according to a certain proportion of ingredients, mixing tank opened after a certain time after automatic discharge, when the slurry discharge is completed to send out empty signal, transport reamer operation, at the same time aluminum powder stirring start, after a certain time, If the temperature of the mixing tank meets the requirements, the lime and cement will automatically feed, when the lime and cement feeding is finished, the empty signal is issued, after a period of time the transmission reamer stops running, and then after a certain period of time, the aluminum powder stirring automatically runs at the same time the aluminum powder automatic feeding, and then after a period of time, the mixer automatically stops, and begins pouring, to the end of this working process, The system waits for the next work order. The feeding of the measuring scale (feeding from the silo or slurry tank to the metering tank) and feeding are interlocked, only after the feeding one the other can be fed, the Simultaneous feeding process is prohibited.

03

POURING PROCESS

fixed casting is adopted, and the mould is moved to the bottom of the pouring mixer. After receiving pouring, it automatically enters the curing room which can control humidity and temperature to accelerate the hardening of the cake.

The traditional cutting machine uses vibration cutting device to cut. Although it improves the labor efficiency, its operation is complicated and the cutting error is big. Dongyue Technology Research and Development Center, on the basis of absorbing the traditional cutting machine, successfully designed a new cutting unit. The main technology reference Germany WEHRHAHN technology, the main reducer, control components using domestic and international well-known products to ensure product stability. Cross cut steel wire using cylinder tightening, frame swing, improve the service life of steel wire and product accuracy. Its outstanding advantage is that the cutting platform is mobile, and the cake and the cross cutting are carried out in one position. When the cake moves to the next position, the longitudinal and horizontal cutting can be completed. This new chain cutting machine has high degree of automation, convenient operation, short cutting cycle, cutting steel wire once through the cake, cutting size is accurate. Greatly shorten the existing production cycle, improve labor productivity.

The traditional cutting machine uses vibration cutting device to cut. Although it improves the labor efficiency, its operation is complicated and the cutting error is big. Dongyue Technology Research and Development Center, on the basis of absorbing the traditional cutting machine, successfully designed a new cutting unit. The main technology reference Germany WEHRHAHN technology, the main reducer, control components using domestic and international well-known products to ensure product stability. Cross cut steel wire using cylinder tightening, frame swing, improve the service life of steel wire and product accuracy. Its outstanding advantage is that the cutting platform is mobile, and the cake and the cross cutting are carried out in one position. When the cake moves to the next position, the longitudinal and horizontal cutting can be completed. This new chain cutting machine has high degree of automation, convenient operation, short cutting cycle, cutting steel wire once through the cake, cutting size is accurate. Greatly shorten the existing production cycle, improve labor productivity.

04

CUTTING SYSTEM

AAC block cutting machine is an important equipment in the AAC production line, is the central link of the AAC block production plant, and has always been the focus of Dongyue Technology Center research and improvement.

This process is equipped with our company’s pouring mixer, which is composed of two parts: mixing drum and pouring arm. The casting arm adopts a telescopic structure to reduce the generation of bubbles during casting. The stirring cylinder is cylindrical, composed of a motor, a stirring shaft and a stirring blade. The discharging at the pouring mouth is controlled by a pneumatic butterfly valve. Ensure the stability of casting, and even improve the output of AAC block, stable quality, effectively reduce the cost of finished products.

This process is equipped with our company’s pouring mixer, which is composed of two parts: mixing drum and pouring arm. The casting arm adopts a telescopic structure to reduce the generation of bubbles during casting. The stirring cylinder is cylindrical, composed of a motor, a stirring shaft and a stirring blade. The discharging at the pouring mouth is controlled by a pneumatic butterfly valve. Ensure the stability of casting, and even improve the output of AAC block, stable quality, effectively reduce the cost of finished products.

05

AUTOCLAVE CURING SYSTEM

The correct selection of autoclave in this process is not only related to the performance of products, but also to the level of production efficiency and energy consumption.

This process is equipped with our company’s pouring mixer, which is composed of two parts: mixing drum and pouring arm. The casting arm adopts a telescopic structure to reduce the generation of bubbles during casting. The stirring cylinder is cylindrical, composed of a motor, a stirring shaft and a stirring blade. The discharging at the pouring mouth is controlled by a pneumatic butterfly valve. Ensure the stability of casting, and even improve the output of AAC block, stable quality, effectively reduce the cost of finished products.

This process is equipped with our company’s pouring mixer, which is composed of two parts: mixing drum and pouring arm. The casting arm adopts a telescopic structure to reduce the generation of bubbles during casting. The stirring cylinder is cylindrical, composed of a motor, a stirring shaft and a stirring blade. The discharging at the pouring mouth is controlled by a pneumatic butterfly valve. Ensure the stability of casting, and even improve the output of AAC block, stable quality, effectively reduce the cost of finished products.

The advantages are as follows:

A.Simple mechanical structure, easy to operate.

B.In the design of the hydraulic system of the separator, a separate control is set for each pair of clamps, and the position of clamping and separating is arbitrarily selected.

C. In order to adapt to blocks of different strength levels, the clamping force of the clamping clamp can be easily adjusted. When the clamping force is set, the pressure will automatically stop and the clamping force will be maintained.

B.In the design of the hydraulic system of the separator, a separate control is set for each pair of clamps, and the position of clamping and separating is arbitrarily selected.

C. In order to adapt to blocks of different strength levels, the clamping force of the clamping clamp can be easily adjusted. When the clamping force is set, the pressure will automatically stop and the clamping force will be maintained.